Designing a New Venue - Part 2

By Giles Moss on April 8th

Wow! After gearing up for our recce weekend (in part 1), it certainly didn't disappoint. We met the landlords, poured over new rooms with tape measures and cameras, chatted in corridors, followed cable trays, failed to open locked doors, even measured a window using a laser measure and trigonometry. And what do we have to show for it? Some notes and heads full of ideas - you get us in a room together and suddenly you’ve got four people designing a theatre at once, it’s a bit mad for a moment but soon the better ideas start to surface and out of the thoughts and discussions a venue starts to take shape.

We’re going to build two new theatres: We’re calling them the Fleming and the Haldane, names chosen from famous Scottish scientists - well we’re operating in the University of Edinburgh’s Lister Learning Centre after all. They’re two very different spaces, and conveniently (for blog purposes anyway) demonstrate the two main ways we design theatres.

The Fleming Theatre is a room where its native shape dictates the theatre design. It’s a lecture theatre with fixed raked seating and an area for a teaching bench at the front. So there is consequently one place we can put a stage, and the audience isn’t moving a centimetre. Being constrained by matters we can’t control means the design pretty much does itself; our design efforts are focused around fitting the truss in, ensure the legs aren’t in gangways and figuring out where to hang the drapes around fire exits.

The Haldane Theatre is much more of an empty canvas. It’s a rectangular room, and that’s it. The stage could be put anywhere! We have a rough audience number to fit in, this comes partly from the room’s nature - a room with a single fire exit has a maximum capacity of 60 people - and partly from what our performing companies are interested in. The Haldane could lend itself to a cosy corner stage, we think it’d be nice, but, again, our companies have indicated they are more interested in an end-on space so that’s what we concentrated on.

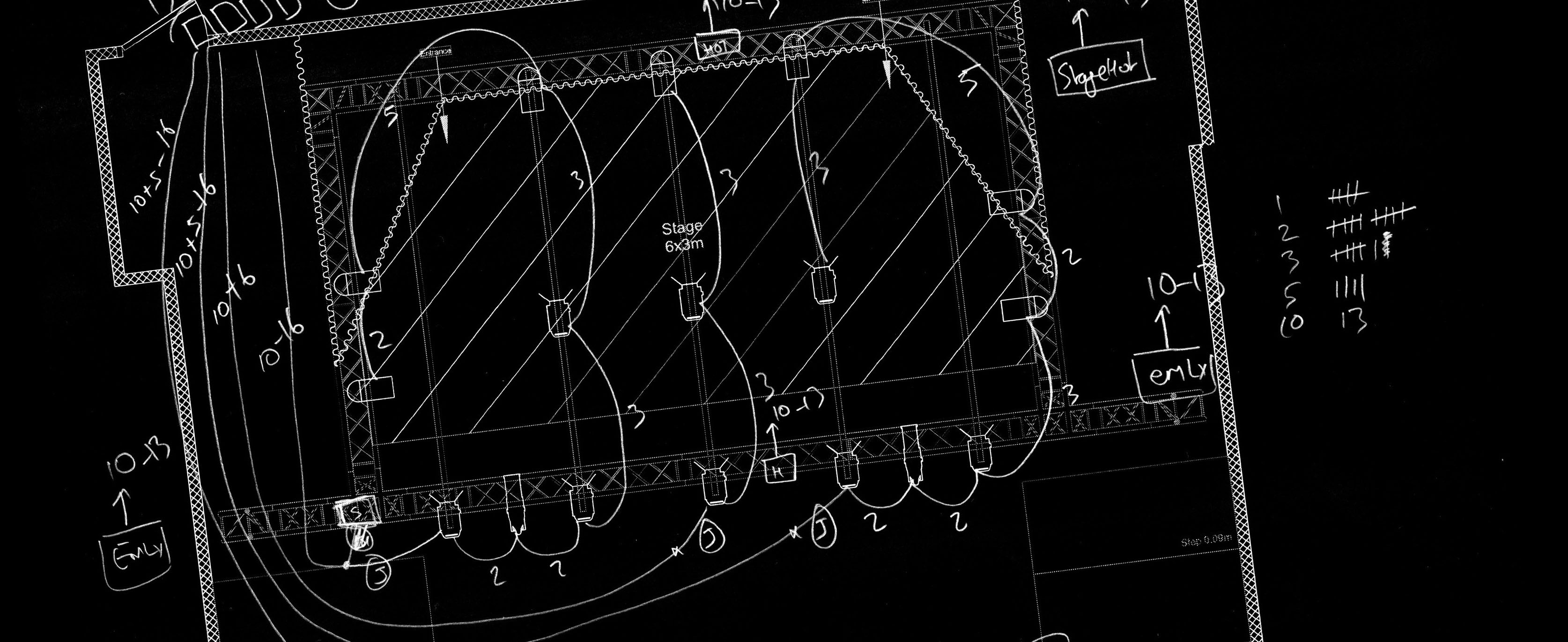

Armed with an idea of the layout and accurate measurements from the recce, it was time to fire up the CAD application and get creative! Our venue CADs are designed with sub-centimetre accuracy and in 1:1 scale. This makes it easy to draw on dimension lines to check widths of critical elements such as aisles and doors, and indeed to check things will actually fit in the spaces we have to play with. Being able to trial and error layouts in this manner means we have a high confidence that what we’re hiring will fit correctly when we come to rig it in July.

A new venue’s plan starts with the room layout, accurately recreated in CAD from our sketch drawings. On to this goes the stage, shortly followed by the truss and the seating. These are the largest blocks to fit in to a room, and are usually closely associated: We can’t put a truss leg through a raised stage and don’t want a stage exit to be right into a truss leg, and so on. We try the room around various ways, often the location of the door and the aisle width requirements means that while the theatre could be either way around, choosing one particular orientation means other things magically fall into place.

We typically drape around the edge of a room to give a nice look, so that needs a run of scaf pipe supported by boom bases. Again, it’s all to scale so we know how many of what length of pipes and drapes we need to hire.

Once we’re happy with the layout of the big items it’s on to the technical rig. The lighting rig needs to suit the space and the style of show we’re likely to programme in. These days with LED kit it’s easier in some ways, as we can get away with fewer fixtures for colour washes, but more complicated in others as we have to run both data and power to all fixtures. Then we look at emergency lighting; are we blocking any building exit signs and therefore need to add more of our own? On the sound side, speakers have dispersion angles which dictate where they need to hang in order to cover the audience blocks, and invariably this ends up with us needing to hang a speaker on sky hooks! But after a few iterations and careful measurements in CAD we reach an optimum design.

So we have a nice, scaled, CAD plan of the space with layers for all the little details like boom base locations, lengths of the scaf pipes, position of the working lights and more. These are exported from CAD as different plans for different purposes. We have two main plans that are shared with our companies: A layout plan showing the seating and stage, and a lighting plan. They don’t need more detail than that, but we do - we create many more plans for our build teams: Plans showing how far trusses need to be from the wall, plans showing how to run the cabling and more. There’s way too much detail to fit on a single page.

With the plans more or less finished it’s time to start talking to the suppliers. We count up how many of every item we need - this involves a printed copy of the plan and getting a pencil out to mark on cable loops between lights - and then send them a big list. They send back a quote, we check it over to make sure it’s what we need, this goes round a few times until we’re all happy it’s going to be the right kit of parts for our construction in July, we agree on the price - and finally we are done! Well, almost: Now we write up the tech specs for our production website and Charles distributes the finalised plans to the companies interested in the spaces. THEN we are finished: new venues - sorted!